Jacketed Reactors Overview

, by Mike Pabich, 7 min reading time

, by Mike Pabich, 7 min reading time

This guide gives an overview of reactors and what they are used for. It also explains in detail how to operate the BVV stainless steel reactors.

Reactors have a multitude of uses in the chemical processing field. They come in many different sizes, shapes, and forms. They are also made out of a variety of materials such as glass or stainless steel. The most basic definition of a reactor is: a vessel that contains a chemical reaction. As you continue reading this post, you will see that a reactor is a tool that can be used for many different processes related to extraction, winterization, distillation, and post-processing. In terms of cannabinoid processing, the most common use for a reactor is large scale winterization. A single or double jacketed reactor is ideal for this process. It allows you to circulate fluid around the exterior or interior jacket to chill the mixture inside. As the mixture becomes colder, the fats and waxes in the mixture begin to coagulate and will fall out of the solution. Reactors can also be used for homogenizing mixtures. They can also be used as stand-alone extraction vessels. Reactors that are used for cannabinoid processing usually have a single or dual jacket system. In a single jacket system, a chiller is used to circulate liquid around the vessel. In a double jacket system, a chiller is used to circulate fluid through the inner jacket, while the outer jacket is used for vacuum insulation to ensure the vessel will maintain the desired temperature. At BVV, we find double jacketed systems to be the most efficient.

You can find our BVV Double Jacketed Glass Reactor Here:

https://shopbvv.com/products/10l-best-value-double-jacketed-glass-reactor

To answer this question, the operator must decide what they want to use the vessel for. If you want to extract from botanical material using ethanol, a stainless steel reactor is recommended. If you need a vessel for large scale dewaxing or related processes, a glass reactor will better suit your needs. The benefit of stainless steel over glass is that you can use positive pressure as opposed to simply vacuum. During extraction, positive pressure is needed to push ethanol through the material. The vacuum will not allow for a full recovery of fluids. You can safely put up to 100psi into our stainless steel reactors which will allow for complete solvent recovery.

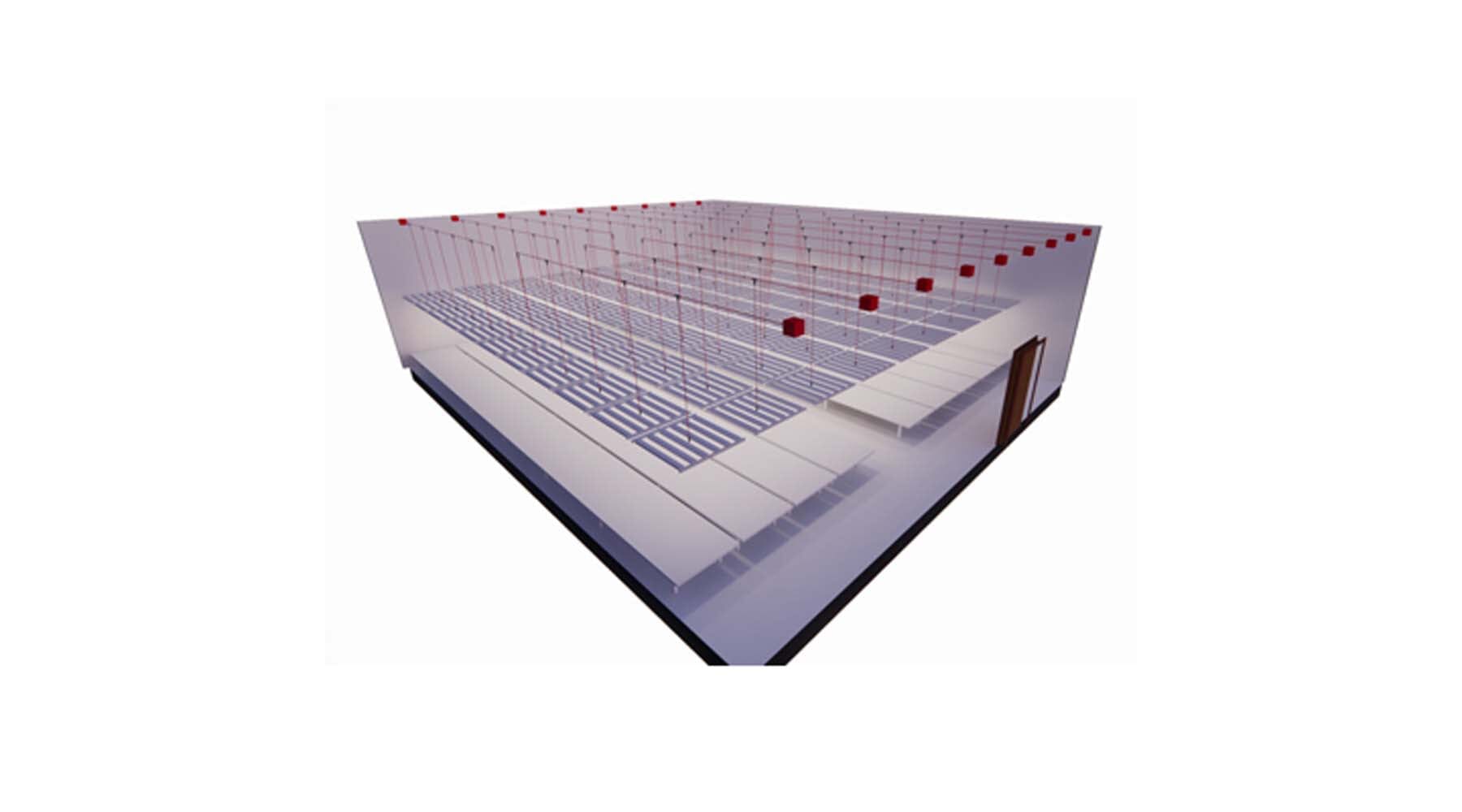

The BVV stainless steel reactors are unique in that, we have designed them for efficient ethanol extraction of botanical material. They offer superior capacity in a small footprint, as well as a modular Tri-Clamp design making them easy to assemble and clean. Each stainless steel reactor includes double jackets. The inner jacket is for fluid circulation and the outer jacket is for vacuum insulation. Each vessel also includes a dedicated solvent input and dump valve as well as a dedicated nitrogen pressure-assist valve, and a vacuum valve. They also include a nitrogen diffusion port to keep the interior dry and free of moisture as well as a bottom fed thermowell for temperature readouts. We offer two different turnkey setups with our reactors as well as the stand-alone vessel. Please refer to the following diagrams for valve layouts:

g>50L Double Jacketed Stainless Steel Reactor Turnkey SetupThis operating procedure is meant to be a starting point for anyone new to using our stainless steel reaction vessels. Once mastered, the operator can adjust the parameters to suit specific needs.

The first reactor turnkey setup includes the 50L double jacketed stainless steel reactor, the 40L Collection Base, a Welch 2.3cfm 4 Head Diaphragm Pump, and a Polyscience 45L AD refrigerated circulator. This turnkey setup is simple to run and allows the operator to quickly input ethanol into the vessel, and then push the ethanol via nitrogen pressure assistance into the collection base. Please refer to the following operating procedure for system setup and use.

-Firstly, load the bottom and elbow with stainless steel ball bearings or a filtration medium of your choice. This will allow the solvent to flow freely but will act as a biological filter for solid particulate. Load botanical material into the vessel. It does not have to be packed tightly nor does it have to be completely filled.

-Before beginning setup, make sure all items in the turnkey setup are accounted for and in proper working order. You will also need nitrogen for pressure assistance. Any standard nitrogen tank will work.

-Begin setup by connecting chiller output to the lower 1/2" jacket valve for fluid circulation. Then connect the chiller input to the upper 1/2" jacket valve for fluid circulation. Once this is done, turn on the chiller and set the desired temperature. Allow chiller to begin cooling (For increased cooling power and faster cool downtimes, it is recommended that the operator uses insulated tubing).

-Connect the supplied inert gas regulator to your nitrogen tank. Once this is done, connect the supplied HVAC hose from the regulator to the red handle valve. This is the dedicated 1/4" MJIC nitrogen assitance connection.

-Connect one of the supplied 1/2" MJIC hoses from the 1/2" MJIC solvent dump at the bottom of the reactor to the 1/2" MJIC solvent dump valve on the collection base.

-Now, connect your vacuum pump to the vacuum manifold. Connect both the 40L collection base and the 50L stainless steel reactor to the manifold via their dedicated 1/4" vacuum valves. Pull a vacuum on both vessels. It does not need to be extremely deep. An evacuation of 5 minutes is sufficient. You may also pull a vacuum on the outer insulation jacket at this time. Once you have pulled a vacuum on all vessels, you may disconnect your vacuum pump from everything except the reaction vessel itself.

-At this point, all valves should be in the closed position and everything should be under vacuum. Your chiller should be at a temperature as well. Connect the second 1/2" MJIC hose to the 1/2" MJIC solvent input on the reaction vessel lid. It is recommended that you store your solvent in a deep freezer so that it is as cold as possible when inputted.You should use about 1 gallon of ethanol per pound of material. Remove lid from your ethanol solvent tank and place the opposite end of the 1/2" MJIC hose into the ethanol. Turn your vacuum pump on and then open 1/2" MJIC solvent input valve. This will pull ethanol out of the solvent tank and into the vessel via vacuum assistance. Watch the inside of the vessel. Once the ethanol has completely flooded the vessel and has risen about an inch above the material, you can close the valve. Allow the ethanol to soak for your desired length of time (a 2-5 minute soak should be sufficient at -20C).

-Using the regulator, input anywhere from 30-100 psi of nitrogen. The amount you input will be dependent on how much solvent you use. Open the blue handled ball valve at the bottom of the vessel and then open the 1/2" MJIC solvent dump valve on the collection base. The ethanol will be pushed into the collection base by the pressurized nitrogen. You may need to put a few more psi of nitrogen into the reactor to push all solvent into the collection base.

-Once all solvent has been pushed into the collection base, bleed off the nitrogen pressure. Once both vessels have reached 0 psi, you can attach rotovap injection valve to the 1/4" dedicated liquid dip tube valve on the collection base. Begin a rotovap procedure to recover your ethanol.

This setup allows for increased efficiency and usability compared to the single reactor turnkey setup. It includes two 50L double jacketed stainless steel reactors, and two Polyscience 45L AD refrigerated circulators. Instead of using the 40L collection base for initial collection, the operator will push the solvent mixture into the second reactor for further winterization. The second vessel can also be used as an ethanol pre-chiller. This setup also includes a 40L collection base so that you can feed your winterized ethanol mixture directly into a rotovap. Follow the operating procedure above for a basic starting point. Substitute the 40L collection base for the second reactor. Once the ethanol mixture is collected into the second reactor, further winterization can be performed and then using nitrogen assistance, the ethanol mixture can be pushed into the collection base to begin a rotovap procedure. You can also use both reactors as material vessels, or one reactor can be used for large batch winterization and separation while the other is used for extraction. The options are quite limitless with the dual reactor setup.